When it comes to aluminium products in India, two terms often pop up—aluminium billets and aluminium rods. If you’re in manufacturing, construction, engineering, or even in the trading business, you’ve probably come across both. But which one is the better fit for your requirement? That’s exactly what we’re going to explore today.

Let’s break it down simply and clearly so that you know exactly what to choose next time.

1. What are Aluminium Billets?

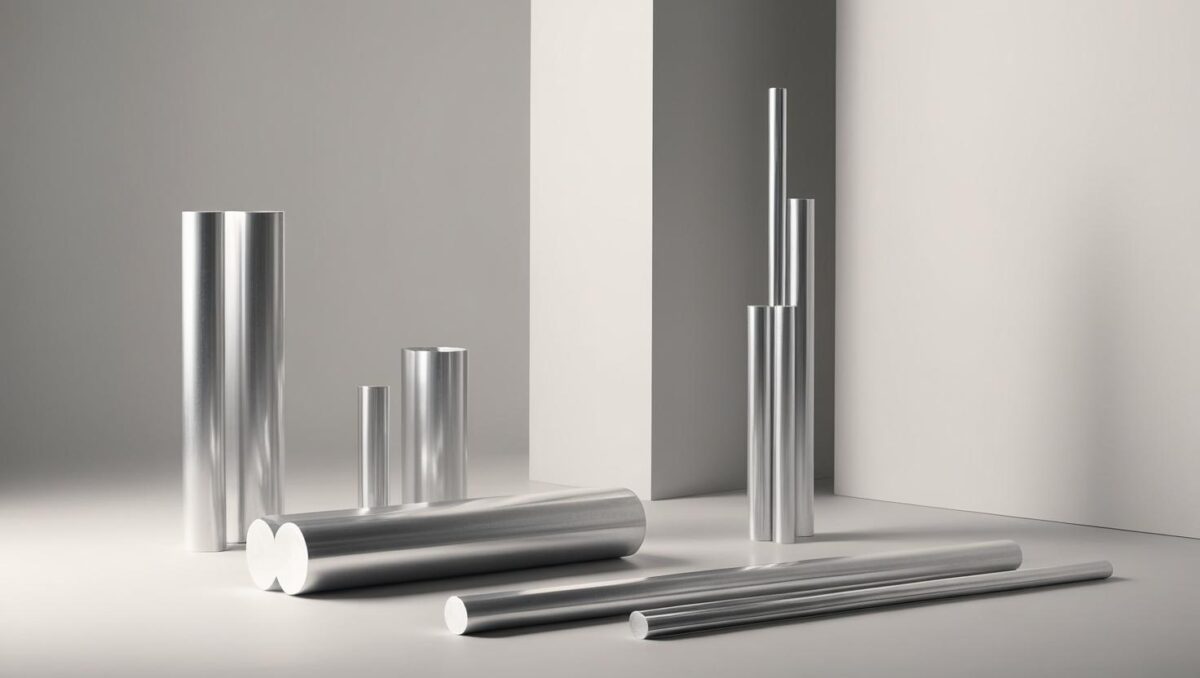

Aluminium billets are semi-finished solid blocks (mostly cylindrical) that are created by casting molten aluminium into molds. These billets act as the raw material for further processing into products like bars, rods, pipes, and other profiles.

In India, aluminium billet manufacturers in India supply these billets to a wide variety of industries—from automotive to construction and even aerospace. These billets are known for:

- Uniform composition

- Superior surface finish

- Excellent strength for forging, extrusion, and rolling

For example, a large part of your car’s bumper, chassis, or even door frames is likely to come from aluminium billets.

2. What are Aluminium Rods?

Aluminium rods, on the other hand, are long, cylindrical products made either by extruding billets or by hot rolling. These are ready-to-use products that find application in sectors like:

- Electrical (as conductors and grounding rods)

- Architecture (railings, supports)

- General-purpose mechanical use

So while billets are raw material, rods are finished or semi-finished products derived from billets.

3. Key Differences Between Aluminium Billets and Rods

Let’s put the differences side-by-side for better clarity:

| Feature | Aluminium Billets | Aluminium Rods |

| Form | Short, thick cylindrical/rectangular blocks | Long, thin cylindrical shapes |

| Manufacturing | Cast from molten aluminium | Extruded or drawn from billets |

| Usage | Raw material for extrusion/forging/rolling | Used directly in electrical and mechanical |

| Strength | Higher, can be heat-treated | Moderate, depends on extrusion quality |

| Flexibility | Custom shapes possible | Limited to standard rod shapes |

This is why billet manufacturers in India focus on quality and composition—it directly affects the final product derived from it.

4. Strength & Performance Comparison

Now here’s the thing—aluminium billets are stronger than rods. Why?

Because billets are the starting point, manufacturers can control the alloy composition, grain structure, and even surface finish right from the base. For instance:

- A billet of alloy 6061 or 6082 can handle high stress, bending, and machining.

- Rods, depending on how they are drawn, may lack this level of structural integrity, especially in high-load environments.

So if you’re producing components for automotive, aerospace, or heavy machinery, billets are the clear winner.

5. Cost Comparison in Indian Market

Cost is always a major factor in any procurement decision. So, let’s talk numbers (approximate as per 2025 market data):

- Aluminium billets in India cost around ₹260 to ₹300 per kg, depending on grade and quantity.

- Aluminium rods can be priced between ₹280 to ₹320 per kg, especially for specific electrical applications.

Though billets may seem slightly cheaper, remember that they need further processing. So if you need a ready-to-use rod, the slightly higher price might be worth it.

But if you’re into manufacturing or custom component production, buying billets and shaping them as per your need will be cost-effective in the long run.

6. Application-Based Selection Guide

Here’s a quick guide on when to use aluminium billets vs rods in India:

✔️ Choose Aluminium Billets if:

- You run a manufacturing or fabrication unit

- You need to make custom profiles, forged parts, or machined components

- Your industry requires tight tolerance and high strength (like aerospace or defence)

✔️ Choose Aluminium Rods if:

- You are in electrical wiring or power transmission

- You need general-purpose cylindrical aluminium parts

- You don’t have in-house extrusion or forging capabilities

7. Availability in Indian Market

India is one of the top aluminium-producing countries globally, thanks to rich bauxite reserves and an ever-expanding industrial sector.

Major states with billet manufacturing hubs:

- Odisha (Angul, Jharsuguda)

- Gujarat (Ahmedabad, Bhavnagar)

- Chhattisgarh

- Maharashtra

Some of the leading aluminium billet manufacturers in India include:

- Hindalco Industries

- BALCO (Bharat Aluminium Company)

- NALCO

- CMR – Known for precision billets for extrusion and forging

These companies also act as reliable billet manufacturers in India for both domestic use and export markets.

8. Sustainability and Recycling

Both aluminium billets and rods are highly recyclable, which is a big plus. However, billets give more flexibility to recycle scrap and remelt into different alloys, making them a better choice for sustainability-focused industries.

India’s aluminium recycling market is expected to grow by 6.5% CAGR by 2028, and billets will be at the center of that transformation.

9. Conclusion: Which One is the Right Fit for You?

To sum it up:

- Go for aluminium billets if you want full control over design, strength, and cost. It’s ideal for industries like automotive, construction, aerospace, and custom engineering.

- Choose aluminium rods if you’re into ready-to-use applications like electrical wiring, supports, or simple machining tasks.

No matter what you choose, make sure you get it from trusted aluminium billet manufacturers in India who ensure quality, consistency, and compliance with standards.

And if you’re exploring options, CMR is one of the top names among billet manufacturers in India, known for superior strength, precision casting, and sustainable production. Whether it’s a large-scale industrial order or a tailored extrusion-grade requirement—CMR’s aluminium billets offer the reliability Indian industries trust.